Why effective QC matters for sample-to-result instruments

Quality control for sample-to-result instruments is not optional, it’s essential. Missing a step or leaving a target out can compromise results and impact patient outcomes. Effective QC ensures instruments behave as expected under clinical conditions, giving laboratories confidence in every result.

3 Key principles of reliable molecular diagnostics QC

Regulatory guidance and best practices consistently emphasize three critical principles for effective QC:

- Patient-like performance: Controls should behave like real patient samples to ensure instruments respond accurately under clinical conditions. (ISO 15189 Section 5.6.2.2 – Quality control materials, CAP – Molecular Pathology Checklist; MOL.34220, MOL.34229, MOL.34270, MOL.34311)

- End-to-end validation: Every stage of the assay — from lysis and extraction through amplification and detection — must be verified. (CAP – Molecular Pathology Checklist (MOL.34220, MOL.34229, MOL.34270, MOL.34311; Code of Federal Regulations Title 42: Public Health, Part 493: Laboratory Requirements (42 CFR 493))

- Complete coverage: Controls should include all organisms the assay is designed to detect. Omitting any target creates blind spots in validation. (CLSI MM06-A2 Section 7.4.1- External Quality Control)

In short, robust QC behaves like patient samples, validates each step and includes all relevant targets. This is the standard upon which our controls are built.

How our controls align with regulatory expectations

Our sample-to-result instrument controls are designed to meet these principles directly:

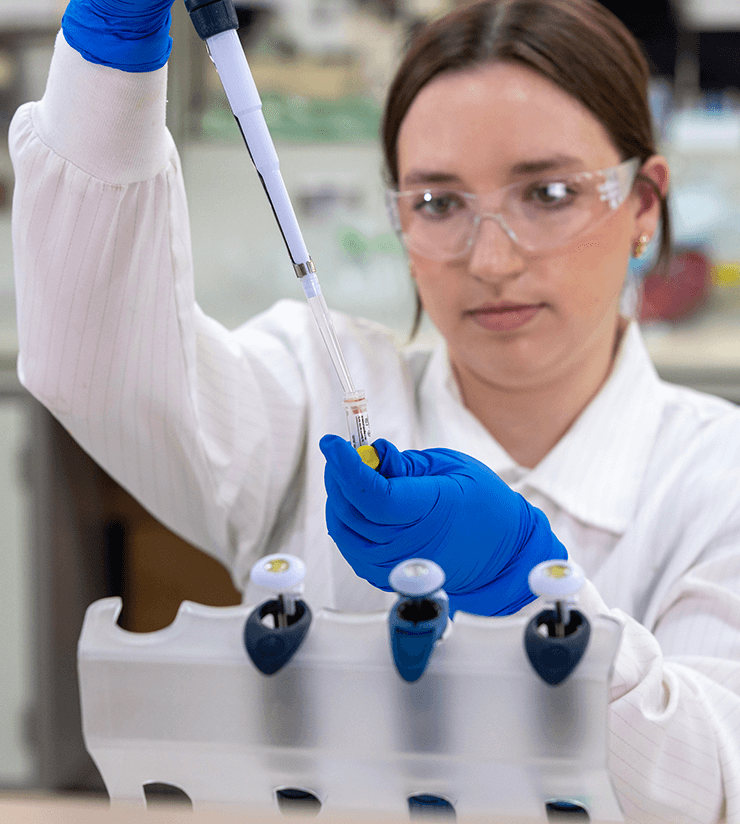

- Patient-like performance: Controls behave like real patient samples, providing an accurate reflection of instrument performance.

- End-to-end validation: Every stage — from lysis and extraction through amplification and detection — is monitored, leaving no step unchecked.

- Complete organism coverage: Every organism that the assay is designed to detect is included, eliminating blind spots in validation.

Side-by-side comparison: coverage and verification

QC step / feature | Our controls | Competitor controls |

Sample lysis | |

|

Extraction | |

|

Amplification | |

|

Detection | | |

Organism coverage | |

|

Is your current QC truly complete?

It’s worth asking: does your current quality control truly validate every step and include all relevant organisms? Missing a target or skipping a step could leave blind spots that affect results.

If you’re considering controls that deliver patient-like performance, full step validation and complete organism coverage, we encourage you to take the next step in one of two ways:

- Not sure yet? Evaluate your current QC

Evaluate your current controls against best practices and regulatory expectations. - Already feeling like it’s time to switch? Book a time with us.

Let’s talk about how our controls can close the gaps in your QC — and in some cases, we may even be able to offset validation costs to make the transition easier.

Whichever option you choose, the goal is the same: giving your lab confidence in every result, every time.

Evaluate your current QC

Quality control for sample-to-result instruments must do more than check a box — it must stand up to regulatory review and ensure patient confidence. Take this quiz to evaluate whether your current QC truly measures up.

Maternal sepsis: how prompt diagnosis saves lives

Intact organisms, blood cells and culture media components can be lysed like a patient sample

Intact organisms, blood cells and culture media components can be lysed like a patient sample No sample-like matrix of red and white blood cells and culture media, limited to no intact organisms

No sample-like matrix of red and white blood cells and culture media, limited to no intact organisms